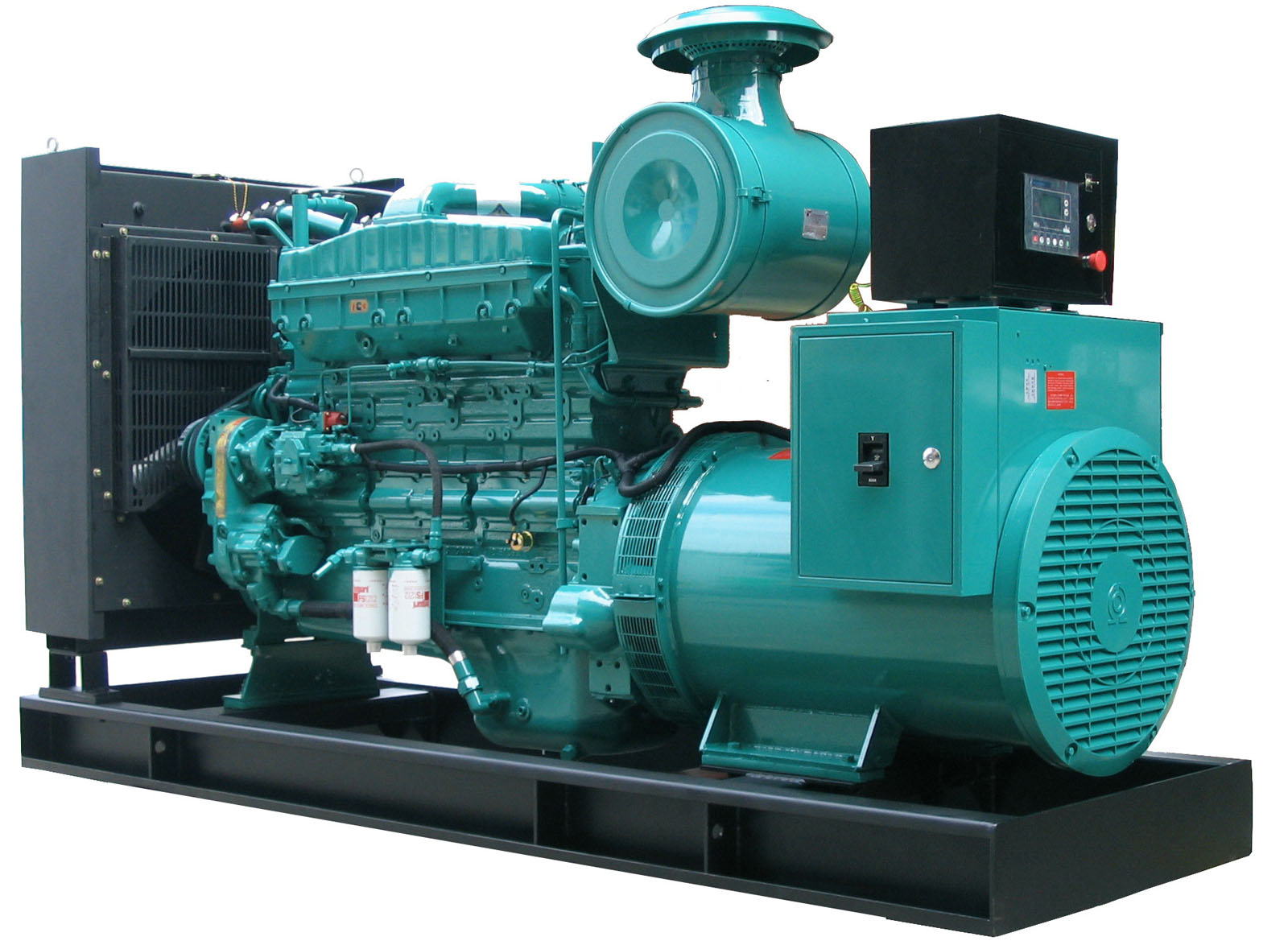

Diesel Standby Generator Maintenance

Diesel standby generators provide uninterrupted power when the electrical grid fails. These generators also provide power at construction sites and other off-grid locations. But they aren’t much use if they don’t start up, especially when power is needed immediately.

However, it’s not uncommon that diesel standby generators won’t start. The most common reasons why they fail to start are that:

- The start switch is turned to OFF instead of AUTO

- The fuel filter is clogged

- The batteries are dead or drained

Owners can easily prevent these problems with regular maintenance. Small investments made in maintaining a standby generator will ensure it runs properly. Maintenance will also prevent owners from spending money on unexpected (and expensive) repairs and will help extend the life of the generator.

The best maintenance program for any generator is the one its manufacturer suggests. So, if you have access to this maintenance program, follow its instructions. However, if it’s unavailable, here’s a guide to help you keep your diesel standby generator operating smoothly.

Weekly Maintenance on Diesel Standby Generators

- Check

- that the start switch is on AUTO

- for warnings

- fuel level

- coolant level

- coolant heater

- charge-air iping

- for fluid leaks

- air filter

- Exercise the engine (Run the engine to keep parts lubricated.)

- Drain the fuel filter

- Drain water from the fuel tank (This need drained because water vapor accumulates and condenses in the tank.)

Monthly Maintenance on Diesel Standby Generators

- Check

- coolant concentration

- engine oil

- batteries

- Clean the generator (Leaks are easy to spot when the unit is clean.)

- Drain exhaust condensate

Biannual Maintenance on Diesel Standby Generators

(A licensed technician should perform this maintenance.)

- Check

- belts

- coolant heater

- cables and connections

- coolant system

- lubrication system

- exhaust system

- air induction system

- DC electrical system

- AC electrical system

- Inspect

- enclosure

- radiator (Remove obstructions and dirt with a soft brush. You can use low-pressure air or water to clean the radiator.)

Annual Maintenance on Diesel Standby Generators

(A licensed technician should perform this maintenance.)

- Change

- engine oil (Oil should be changed after every 100 hours of operation.)

- oil filter

- spark plugs

- fuel filter

- air filter

- crankcase breather

- coolant

- fuel (Fuel degrades over time. You should use it before it degrades.)

- Flush or clean coolant system (if needed)

- Perform load bank testing

The above guide is only a suggestion. A number of factors will determine how often and what maintenance your diesel standby generator will require. Some factors that will affect your maintenance schedule include extreme temperatures, exposure to the elements, and whether you use the generator as your prime power source.